Overhead lines

Overhead lines or overhead wires are used to transmit electrical energy to trams, trolleybuses or trains at a distance from the energy supply point. These overhead lines are known variously as

- Overhead contact system (OCS)—Europe, except UK and Spain

- Overhead line equipment (OLE or OHLE)—UK

- Overhead wiring (OHW)—Australia

- Catenary—United States, UK, Singapore (North East MRT Line) [1], Canada and Spain.

In this article the generic term overhead line is used.

Overhead line is designed on the principle of one or more overhead wires situated over rail tracks, raised to a high electrical potential by connection to feeder stations at regular intervals. The feeder stations are usually fed from a high-voltage electrical grid.

Contents |

Overview

Electric trains that collect their current from an overhead line system use a device such as a pantograph, bow collector, or trolley pole. The device presses against the underside of the lowest wire of an overhead line system, the contact wire. The current collectors are electrically conductive and allow current to flow through to the train or tram and back to the feeder station through the steel wheels on one or both running rails. Non-electric trains (such as diesels) may pass along these tracks without affecting the overhead line, although there may be difficulties with overhead clearance. Alternative electrical power transmission schemes for trains include third rail, batteries, and electromagnetic induction.

This article does not cover regenerative braking, where the traction motors act as generators to retard movement and return power to the overhead.

Construction

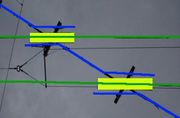

To achieve good high-speed current collection it is necessary to keep the contact wire geometry within defined limits. This is usually achieved by supporting the contact wire from above by a second wire known as the messenger wire (UK) or catenary (US & Canada). This wire is allowed to follow the natural path of a wire strung between two points, a catenary curve, thus the use of catenary to describe this wire or sometimes the whole system. This wire is attached to the contact wire at regular intervals by vertical wires known as droppers or drop wires. The messenger wire is supported regularly at structures, by a pulley, link, or clamp. The whole system is then subjected to a mechanical tension.

As the contact wire makes contact with the pantograph, the carbon surface of the insert on top of the pantograph is worn down. Going around a curve, the "straight" wire between supports will cause the contact wire to cross over the whole surface of the pantograph as the train travels around the curve, causing an even wear and avoiding any notches. On straight track, the contact wire is zigzagged slightly to the left and right of centre at each successive support so that the pantograph wears evenly.

The zigzagging of the overhead line is not required for trolley-based trams or trolleybuses.

Depot areas tend to have only a single wire and are known as simple equipment. When overhead line systems were first conceived, good current collection was possible only at low speeds, using a single wire. To enable higher speeds, two additional types of equipment were developed:

- Stitched equipment uses an additional wire at each support structure, terminated on either side of the messenger wire.

- Compound equipment uses a second support wire, known as the auxiliary, between the messenger wire and the contact wire. Droppers support the auxiliary from the messenger wire, and additional droppers support the contact wire from the auxiliary. The auxiliary wire can be constructed of a more conductive but less wear-resistant metal, increasing the efficiency of power transmission.

Dropper wires traditionally only provide physical support of the contact wire, and do not join the catenary and contact wires electrically. Contemporary systems use current-carrying droppers, which eliminate the need for separate wires.

For tramways there is often just a simple contact wire and no messenger wire.

In situations where there is limited clearance to accommodate wire suspensions systems such as in tunnels, the overhead wire may be replaced by rigid overhead rail. This was done when the overhead line had to be raised in the Simplon Tunnel to accommodate taller rail vehicles.

Parallel overhead lines

An electrical circuit requires at least two conductors. Trams and railways use the overhead line as one side of the circuit and the steel rails as the other side of the circuit. For a trolleybus there are no rails to send the return current along—the vehicles use rubber tires and the normal road surface. Trolleybuses use a second parallel overhead line for the return, and two trolley-poles, one contacting each overhead wire. The circuit is completed by using both wires.

Germany

In Germany there are special overhead power lines for single phase AC traction current with a frequency of 16⅔ hertz. Most of these lines, which are all operated with a voltage of 110 kV (the voltage of the supply cables, not the voltage of the railway overhead lines which is 15 kV) have four conductor cables for two circuits. As a rule at traction current lines, the single-level arrangement of the conductor cables is used. A traction current pylon is a pylon with at least carry one electric circuit for traction current. For traction current lines with four circuits (eight conductor cables) frequently two-level arrangements of conductors are used, at which one crossbar carries four conductor cables. For traction current lines used for supplying new high-speed rail tracks, three-level arrangements of conductors are used. Thereby are on the lowest crossbar four, and on the upper crossbars two, conductor cables mounted. The three-level arrangement is also used for traction current lines with six electric circuits (12 conductor cables).

There are further, in particular for the power supply of rapid transit railways operated with alternating current, overhead line pylons with crossbars for 110 kV traction current powerlines above the contact wire in use. There are also pylons that carry electric circuits for traction current and for three-phase alternating current of the public power grid.

Tensioning

Catenary wires are kept at a mechanical tension because the pantograph causes oscillations in the wire and the wave must travel faster than the train to avoid producing standing waves that would cause the wires to break. Tensioning the line makes waves travel faster.

For medium and high speeds, the wires are generally tensioned by means of weights or occasionally by hydraulic tensioners. Either method is known as auto-tensioning (AT), and ensures that the tension in the equipment is virtually independent of temperature. Tensions are typically between 9 and 20 kN (2,000 and 4,500 lbf) per wire.

For low speeds and in tunnels where temperatures are constant, fixed termination (FT) equipment may be used, with the wires terminated directly on structures at each end of the overhead line. Here the tension is generally about 10 kN (2,200 lbf). This type of equipment will sag on hot days and hog on cold days.

Where AT is used, there is a limit to the continuous length of overhead line which may be installed. This is due to the change in the position of the weights with temperature as the overhead line expands and contracts. This movement is proportional to the tension length, i.e. the distance between anchors. This leads to the concept of maximum tension length. For most 25 kV OHL equipment in the UK, the maximum tension length is 1970 m.

An additional issue with AT equipment is that, if balance weights are attached to both ends, the whole tension length will be free to move along track. Therefore, a midpoint anchor (MPA), close to the centre of the tension length, restricts movement. MPAs are often fixed to low bridges. Therefore, a tension length can be seen as a fixed centre point, with the two half tension lengths expanding and contracting with temperature.

Breaks

To allow maintenance to sections of the overhead line without having to turn off the entire system, the overhead line system is broken into electrically separated portions known as sections. Sections often correspond with tension lengths as described above. The transition from section to section is known as a section break and is set up so that the locomotive's pantograph is in continuous contact with the wire.

For bow collectors and pantographs, this is done by having two contact wires run next to each other over a length about four wire supports: a new one dropping down and the old one rising up until the pantograph smoothly transfers from one to the next. The two wires never touch (although the bow collector/pantograph is briefly in contact with both wires). In normal service, the two sections are electrically connected (to different substations if at or near the halfway mark between them) but this can be broken for servicing.

On overhead wires designed for trolley poles this is done by having a neutral section between the wires, requiring an insulator. The driver of the tram or trolleybus must turn off the power when the trolley pole passes through, to prevent arc damage to the insulator.

Sometimes on a larger electrified railway, tramway or trolleybus system, it is necessary to power different areas of track from different power grids, the synchronisation of the phases of which cannot be guaranteed. (Sometimes the sections are powered with different voltages or frequencies.) There may be mechanisms for having the grids synchronised on a normal basis but events may cause desynchronisation. This is no problem for DC systems but, for AC systems, it is highly undesirable to connect two unsynchronised grids. A normal section break is insufficient to guard against this, since the pantograph briefly connects both sections.

Instead, a phase break or neutral section is used. This consists of two section breaks back-to-back so that there is a short section of overhead line that belongs to neither grid. If the two grids are synchronized, this stretch of line is energized (by either supply) and trains run through it normally. If the two supplies are not synchronized, the short isolating section is disconnected from the supplies, leaving it electrically dead, ensuring that the two grids cannot be connected to each other.

The sudden loss of power over the phase break would jar the train if the locomotive was at full throttle, so special signals are set up to warn the crew. When synchronization is lost and the phase break is deenergized, the train's operator must put the controller (throttle) into neutral and coast through an isolated phase break section.

On the Pennsylvania Railroad, phase breaks were indicated to train crews by a metal sign hung from the overhead with the letters PB on it, created by drilled holes. When the phase break was "dead", a signal with eight lights in a circular pattern indicated so.

Transnet Freight Rail in South Africa has permanent magnets between the rails at both sides of the neutral section where two phases are separated. These are detected by equipment on the locomotive, which disconnect and reconnect power from the pantographs.

Crossings

Trams draw their power from a single overhead wire at about 500 to 750 V, while trolleybuses draw their power from two overhead wires at a similar voltage. Because of that, at least one of the trolleybus wires must be insulated from tram wires. This is usually solved by the trolleybus wires running continuously through the crossing, with the tram conductors a few centimetres lower. Close to the junction on each side, the wire merges into a solid bar running parallel to the trolleybus wires for about half a metre. Another bar similarly angled at its ends is hung between the trolleybus wires. This is electrically connected above to the tram wire. The tram's pantograph bridges the gap between the different conductors, providing it with a continuous pickup.

Where the tram wire crosses, the trolleybus wires are protected by an inverted trough of insulating material extending 20 or 30 mm below.

Until 1946, there was a level crossing in Stockholm, Sweden between the railway south of Stockholm Central Station and a tramway line. The tramway operated on 600-700 V DC and the railway on 15 kV AC. Some crossings between tramway/light rail and railways are still extant in Germany. In Zürich, Switzerland the VBZ trolleybus line 32 has a level crossing with the 1,200 V DC railway to mount Uetliberg; at many places in the town, trolleybus lines cross the tramway. In the Swiss village of Suhr, the WSB tramway operating at 1,200 V DC crosses the SBB line at 15 kV AC. In some cities, trolleybuses and trams have shared the same positive (feed) wire. In such cases, a normal trolleybus frog can be used.

Another system that has been used is to coincide section breaks with the crossing point so that the crossing is electrically dead.

Australia

Many cities had trams and trolleybuses both using trolley pole current collection. They used insulated crossovers which required tram drivers to put the controller into neutral and coast through. Trolleybus drivers had to either lift off the accelerator or switch to auxiliary power.

In Melbourne, Victoria, tram drivers put the controller into neutral and coast through section insulators, indicated by insulator markings between the rails.

Melbourne has four level crossings between electrified suburban railways and tram lines. They have complex switching arrangements to separate the 1,500 V DC overhead of the railway and the 650 V DC of the trams, called an overhead square.[2] Proposals have been put forward which would see these crossings grade separated or the tram routes diverted.

Queensland uses 25 kV AC overhead traction with booster transformers in the Brisbane suburban area and auto transformers elsewhere.

Western Australia (Perth city) uses 25 kV AC overhead traction with booster transformers.

Greece

In Athens, there are two crossings between tram and trolleybus wires, at Vas. Amalias Avenue and Vas. Olgas Avenue, and at Ardittou Street and Athanasiou Diakou Street. They use the above-mentioned solution.

From the opening of the tram system in the summer of 2004, trams and trolleybuses in the direction of Pagrati shared the same exclusive lane, about 400m long, on the far right side of Vas. Olgas Avenue, with tram and trolleybus wires side-by-side above a narrow lane of road. The trolleybus wires were on the far right of the lane, away from the trams' (very wide) pantographs. Trolleybus drivers were required to drive very slowly because the trolley poles were extended to their limits. A change of route for trolleybuses was implemented in mid-2005, ending this arrangement.

Italy

In Milan, most tram lines cross the circular trolleybus line once or twice, so crossings between overhead tram and trolleybus wires are quite commonplace. Trolleybus and tram wires run parallel in some streets, like viale Stelvio and viale Tibaldi.

Multiple overhead lines

There are and were some railways that used two or three overhead lines, usually to carry three-phase current to the trains. Nowadays, three-phase AC current is used only on the Gornergrat Railway and Jungfraujoch Railway in Switzerland, the Petit train de la Rhune in France, and the Corcovado Rack Railway in Brazil; until 1976, it was widely used in Italy. On these railways, the two conductors of the overhead lines are used for two different phases of the three-phase AC, while the rail was used for the third phase. The neutral was not used.

Some three-phase AC railways used three overhead wires. These were an experimental railway line of Siemens in Berlin-Lichtenberg in 1898 (length: 1.8 kilometres), the military railway between Marienfelde and Zossen between 1901 and 1904 (length: 23.4 kilometres) and an 800-metre-long section of a coal railway near Cologne, between 1940 and 1949.

On DC systems, bipolar overhead lines were sometimes used to avoid galvanic corrosion of metallic parts near the railway, such as on the Chemin de fer de la Mure.

All systems of multiple overhead lines have the disadvantage of high risk of short circuits at switches and therefore tend to be impractical in use, especially when high voltages are used or when trains run through the points at high speed.

Overhead catenary

A catenary is a system of overhead wires used to supply electricity to a locomotive, streetcar, or light rail vehicle which is equipped with a pantograph.

Unlike simple overhead wires, in which the uninsulated wire or cable is attached by clamps to closely spaced crosswires, themselves supported by line poles, catenary systems use at least two wires. One wire, called the catenary or messenger wire, is hung at a specific tension in the shape of a mathematical catenary between line structures. A second wire is held in tension by the messenger wire, and is attached to it at frequent intervals by clamps and connecting wires. The second wire is straight and level, parallel to the rail tracks, suspended over it as the roadway of a suspension bridge is over water.

Simple wire installations are common in light rail applications, especially on city streets, while more expensive catenery systems are especially suited to high-speed operations.

The Northeast Corridor in the United States features electrified catenary over a 600-mile or 1000 km distance between Boston, Massachusetts and Washington, D.C., providing power for Amtrak's high-speed Acela Express and other trains. Several commuter rail agencies, including MARC, SEPTA, NJ Transit, Metro-North utilize the catenary to provide local service along the Northeast Corridor.

In Cleveland, Ohio the interurban/light rail lines use overhead wires, and the heavy rail line also uses overhead wires, instead of a third rail. This was due to a city ordinance intended to limit air pollution from the large number of steam trains passing through the Cleveland between the east coast and Chicago. Trains switched from steam to overhead catenary electric locomotives at the Collinwood Rail Yards about 10 miles (16 km) east of Downtown Cleveland and similarly at Linndale on the west side. When Cleveland constructed its rapid transit (heavy rail) line between the airport, Downtown Cleveland and beyond it employed similar overhead catenary technologies that the railroads used, and were able to utilize railroad electrification equipment left over after railroads switched from steam to diesel locomotives. Consequently, light and heavy rail public transit systems share trackage for about 3 miles (4.8 km) along the Cleveland Hopkins International Airport Red (heavy rail) line, Blue and Green interurban/light rail lines between Cleveland Union Terminal and just past East 55th Street station, where the heavy- and light-rail line tracks separate.

The Blue Line, running through suburbs northeast of Boston, Massachusetts, uses overhead power lines.

Height

The height of overhead wiring can create hazards at level crossings, where it may be struck by road vehicles. The wiring in most countries is too low to allow Double stack container trains. The Channel Tunnel has an extended height overhead line to accommodate double-height car and truck transporters. India is proposing a network of freight only lines, which would almost certainly be electrified with extra height wiring and pantographs that can reach it.

Technical advances lower running costs

The introduction of supercapacitors has promised to drop electrical running costs for trains powered by overhead lines or third rails. Kinetic braking energy is reclaimed by storing electrical energy in supercapacitors onboard the vehicle. This stored energy is used when accelerating the train, when high current is needed. The supplementing supercapacitors reduce current drawn through the electrical supply during acceleration and puts less strain on the distribution system.

Later developments locate banks of supercapacitors at track side. All trains on the system can then use the stored energy in the supercapacitors to supplement the energy drawn through a third rail or overhead wires. Trackside location reduces vehicle weight and creates more onboard space. However, such locations would require additional equipment to charge the supercapacitors from the overhead line voltage and to generate supplementary power at the voltage and frequency of the overhead line from the stored energy.

Claimed energy reduction is around 30%. Electric railway systems can be more competitive and a real economical alternative to automobiles.

The technology can be used equally well for diesel electric locomotives, where 25% to 40% reduction in energy consumption is claimed, however only onboard location of supercapacitor banks is feasible. (This technology equally applies to road vehicles that use electric motors for propulsion, such as hybrid cars and buses.) Any electrical equipment that requires regular braking can reduce operating costs using supercapacitors. Reduced operating costs of elevators on underground railways would be a great benefit to operators and adding to their economic competitiveness.

An additional benefit is that emissions from generating plants and diesel-electric locomotives will be decreased.

Since 2003, the Mannheim Stadtbahn in Germany has operated a light-rail vehicle using electric double-layer supercapacitors to store braking energy.[3][4]

A number of companies are developing electric double-layer supercapacitor technology. Siemens AG is developing mobile energy storage based on double-layer supercapacitors called Sibac Energy Storage [5] Sitras SES, are developing stationary trackside version.[6] The company Cegelec is also developing an electric double-layer capacitor-based energy storage system.

History

In 1881 the first tram with overhead lines was presented by Werner von Siemens on the International Electric Exposition in Paris 1881 but the installation was removed after that event. In October 1883, the first permanent tram service with overhead lines was started on Mödling and Hinterbrühl Tram in Austria. These trams had bipolar overhead lines, consisting of two U-pipes, in which the pantographs hung and ran like shuttles. In April to June 1882, Siemens had tested a similar system on his Electromote, an early percursor of the trolleybuses.

Much simpler and more functional was an overhead wire in combination with a pantograph borne by the vehicle and pressed at the line from below. This system, for rail traffic with an unipolar line, was invented by Frank J. Sprague in 1888. Since 1889, it was used at the Richmond Union Passenger Railway in Richmond, Virginia. That was the onset of worldwide use of electric traction.

See also

- Bow collector

- Pantograph

- Trolley pole

- Frank J. Sprague

- Lineman

- Metro-North Railroad, a US commuter railway serving New York and Connecticut, using overhead wires, third rail, and diesel locomotives.

- List of current systems for electric rail traction

References

- ↑ SBS Transit

- ↑ TMSV: Tramway level crossings in Victoria

- ↑ UltraCaps win out in energy storage. Richard Hope, Railway Gazette International July 2006

- ↑ M. Steiner. MITRAC Energy Saver. Bombardier presentation (2006).

- ↑ Siemens AG Sibac ES Sibac ES Product Page (as of November 2007)

- ↑ Siemens AG Sitras SES Sitras SES Product Page (as of November 2007)

External links

|

|||||